- Home

- genuine for reason

Genuine John Deere Tractor Parts

Reliability and Performance at its best!

John Deere delivers quality parts that are tailored to enhance the performance, comfort and reliability of your tractor. Genuine tractor parts operate, fit and function perfectly since the design and specification is controlled by John Deere – just the same as when the tractor was originally made. Your John Deere tractor will stay as reliable as the day it was purchased – for years and years to come.

ALTERNATORS AND GENERATORS

John Deere Reman Rotating Electrical

One good turn deserves another - and another.

John Deere Reman alternator and generator products are built to produce John Deere power and dependability – at a cost that makes sense.

Your Benefits:

- John Deere quality:

- Parts go beyond repair. They’re completely disassembled and remanufactured.

- Voltage and amperage testing is done at both idle and load speeds.

- Rotors and stators are tested and insulated to meet John Deere standards.

- Attractive pricing.

- Known repair costs up front.

- Protection with a one-year unlimited-hour parts and labour warranty on dealer installations.

PISTONS

John Deere piston bowls

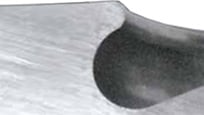

Stronger for a reason

Improve your engine’s reliability, durability and uptime:

- Fibre-reinforced bowl lip provides 50 percent higher fatigue strength

- Design of the John Deere bowl lip dissipates combustion heat more quickly

John Deere piston bores

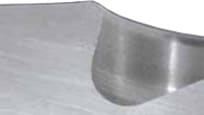

Offset for a reason

The offset bore in a John Deere piston increases engine performance and service life:

- Reduces vibration noise

- Reduces mechanical stress

- Reduces surface wear

Genuine John Deere fibre-reinforced bowl lip

Competitor A bowl lip not reinforced

Competitor B bowl lip not reinforced

FUEL INJECTION COMPONENTS

The John Deere Reman line of fuel-injection products are designed in response to customer demands to minimize downtime and provide the customer a low-cost repair alternative.

Your Benefits:

- Reduced downtime by providing an exchange of fuel components

- Price competitive versus fuel injection rebuilt options

- Known repair costs up front

- A one-year, unlimited-hour parts and labour warranty if dealer installed*

- Completely remanufactured, not replacement of failed parts only

* This coverage includes both parts and labour when your dealer installs the component on your machine; otherwise the coverage is for parts only.

ENGINE OVERHAUL KITS

Make your engine like new again.

John Deere Engine Overhaul Kit boosts performance and reduces oil consumption.

Does your engine feel like it’s not running at its best or do you have to top up the oil more often than normal?

Restore the original performance of your machine’s engine with the only kit that meets original equipment specifications.

Standard kit includes:

- Rod, main and thrust bearings

- Thrust washers

- Oil pan split gasket

- Pre-assembled piston and liner kits

- Liner packings

- Front and rear seals

- Overhaul gasket set

- Snap rings

Expanded kit includes:

- Rod bolts and bushings

- Piston pins

- Camshaft bushings

Keep your engine running perfectly with genuine John Deere oil, coolants and filters.

ENGINE OIL FILTERS

Helping you – and your engine – breathe easier.

The quality of the oil filters you fit has a direct effect on how well your John Deere engine performs. So next time you change a filter, insist on the best: genuine John Deere filters.

Oil filters: the inside story

Other filters may look the same on the outside – but inside, there can be a world of difference. From the quality of the filter material to the sealing rings and spring tensioners that ensure top performance, John Deere gives you the quality your tractor deserves. So don’t risk your valuable equipment unnecessarily. If it doesn’t say John Deere on the label, the filters you’re looking at weren’t made solely for John Deere equipment.

Fit and forget

Only genuine John Deere filters come with peace of mind fitted as standard.

- Long lasting performance – right through to the next service interval

- Outstanding efficiency – custom-built for your equipment

- Maximum protection – for you and your investment

See for yourself

As you’ll see below, many so-called ‘bargain’ filters cut corners to make you think they’re cheaper. They skimp on paper thickness, use a thinner spring … even leave out a seal altogether. No wonder they need changing so often!

Genuine John Deere Oil Filter

Look-alike oil filter

Genuine John Deere Oil Filter

Look-alike oil filter

Why quality pays

John Deere filters, on the other hand, offer real value for money. Because we never compromise on quality, you can be sure they’ll do the job properly, for as long as they’re supposed to. Keeping your engine purring smoothly for years to come.

Inner Component Design (Deflecting chamber)

Genuine John Deere oil filters are correctly sprung, so they fit properly and stay put.

Look-alike oil filters use weaker non-spec. spring designs, so filter elements can wobble or leak.

Dimensions

Genuine John Deere oil filters use a high quality filter paper with a higher density which lets no harmful particles and also no light through - as the John Deere quality standard requires!

Look-alike oil filter with inferior filter paper which is far more permeable to particles and not so thick which can easily be proven by a light test.

ENGINE BELTS

Minimum wear. Maximum reliability

Choose John Deere belts and combine excellent technical features with optimum temperature-resistant attributes for maximum reliability.

John Deere engine belts: a firm grip on advanced technology.

Special materials ensure the highest reliability

John Deere’s rubber v-belt mixture has been specifically formulated to meet the highest demands. As a result, the belts are more resistant to extreme temperatures and external influences: • Heat resistant – up to 120° C • Cold resistant – down to –25° C • Highly resistant to the abrasive affects of oil, ozone and fuel.

Durability Test shows why John Deere v-belts are more reliable

A standard v-belt, an original-equipment quality chloroprene v-belt and a John Deere v-belt with its special rubber mixture were chosen for the test. Each was installed on a test stand with a fir-tree configuration. The simulated ambient temperature was then set at 120° C and the belts were accelerated to a driver speed of 5000 rpm. The test ended when a belt had over 10 rib cracks within 100 mm of each other or one of the ribs failed.

Lasting quality

Thanks to an optimal combination of materials and technical features, the John Deere v-belt held up three times longer than the standard v-belt. It was twice as reliable as the OE chloroprene v-belt!

MUFFLERS

Built for performance

Reduce noise and increase fuel efficiency with high quality John Deere mufflers

Surface Coating

Genuine John Deere muffler with hot dip aluminised coating

Surface provides high heat and corrosion resistance for long life

Non-genuine muffler with painted or enamel coating

Coating burns off, meaning lower corrosion protection and shorter life

Canister Assembly

Genuine John Deere muffler with folded design

Allows for thermal expansion, offering high stability and durability against vibration and cracks

Non-genuine muffler with welded design

Cannot sufficiently compensate for thermal expansion, leading to lower stability and less resistance to vibration, cracks and leaks

Inner Component Design (Deflecting chamber)

Genuine John Deere muffler with half shell design

Rounded design allows optimised flow of exhaust stream for lower backpressure, improved fuel consumption and a more responsive engine.

Non-genuine muffler with angled tubes

Angled design causes exhaust gases to swirl, leading to higher backpressure and increased fuel consumption.

Dimensions

Genuine John Deere muffler with perfect fit

Meets John Deere specifications exactly for a perfect fit.

Non-genuine muffler with wrong size

Does not meet John Deere specifications (particularly mounting points and entrance and exit tubes), so is difficult to fit, with potential risk of damage.

CAB GLASS

What are the demands placed on cab glass? Naturally, they provide protection from the weather and noise. But, as innumerable tests and ten thousand practical applications have shown, John Deere panes comply with John Deere specifications and legal requirements better than these look-alike products. And that means added safety for you, the operator.

In recent tests with look-alike competitors, we covered the following aspects:

- Manufacturing quality

- Hole dimensions

- Ease of installation

- Leak-proof aspects

John Deere panes are custom-made.

As the inserts show, the dimensions of the look-alike panes do not correspond to those of the John Deere original glass. Conclusion: Expect precision John Deere quality or expect rattles and leaks.

John Deere panes hit the mark. As you can see, the look-alike panes do not! Conclusion: Expect a snug John Deere fit or expect to have a fit when installing look-alike pane!

This third-party pane is well off the mark. Trouble is on the way.

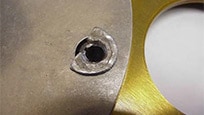

Assembly holes on John Deere glass aren’t rough around the edges.

To prevent possible cracking, the edges of John Deere assembly holes are bevelled. The holes of the look-alike panes often are not. As you can clearly see, tiny cracks have already appeared around the unfinished edges. Conclusion: use John Deere glass or get used to a cracked view.

Genuine John Deere pane

A John Deere bevelled edge

Look-alike pane

An edge that is not bevelled

John Deere panes keep you safer and drier.

The rain test shows what can happen when look-alike panes are used. The rear window does not fit properly and will not close properly. The results: a steamy window and a clammy cab!

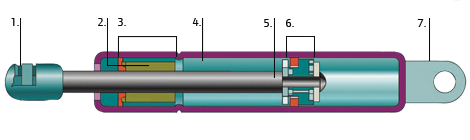

GAS STRUTS

Open your doors, windows and covers easily It’s easy to think gas struts are all the same and just buy on price. But if one fails you soon know about it when a door unexpectedly slams shut on your hand or it becomes really hard to open the engine hood or shut a window. So it’s important you make the right choice when it comes to replacement. John Deere gas struts are built for a long and reliable life with a comfortable action for opening and closing. Here’s our quick buyer’s guide to the essential features of the perfect gas strut:

- Double sealing system The gas pressure inside a strut is very high (150 bar or 2175 psi) so it’s vitally important it doesn’t leak or it won’t work. Our struts have a special double sealing system which keeps the pressure in and ensures a smooth action and a long service lifetime.

- Corrosion resistant materials The piston rod has a corrosion resistant coating. In salt spray tests our struts were capable of withstanding a minimum of 144 hours. In the same test, look-alike struts failed after just 24 hours.

- Scratch free surfaces If the piston rod gets scratched it can damage the seal and gas could leak out, reducing the effectiveness of the strut. Our cylinder pistons have a special scratch-free surface treatment which reduces wear, improves cylinder performance and lengthens the strut’s life.

- Strong fittings The fittings are also an essential part of the strut’s inherent strength. Ours have specially designed fittings which protect the strut from torsional forces, ensuring a longer life.

- Special fitting to reduce torsional forces - Long life

- All weather lubricating oil - Built and tested to agricultural specification

- Durable seal - Maintenance free

- Heavy duty tube - Corrosion proof components

- Stainless steel salt spray tested - Guaranteed

- Precision-engineered piston - Smooth action

- Machined coupling - Easy to fit

BEARINGS

Better materials make better bearings

Unlike many of our competitors, we insist on only the best high-carbon and chromium-based steel to ISO standards for our wheel and other bearing applications. The resulting spherical chrome-carbides create a metallurgical surface feature which reduces friction and stress.

The consistent hardness of our bearings avoids material deformations. And because they don’t magnetise, they don’t attract metallic impurities.

Genuine John Deere bearings are made of a premium grade steel that guarantees superior performance under even the toughest conditions.

Look-alike bearings usually aren’t up to our high standards. So, in the end, you pay the price even if the alternative bearings were a bit cheaper.

Survival of the fittest

John Deere tractors perform under gruelling conditions. Loads are intense, temperatures soar and plummet, dust and particles are a constant source of possible contamination. Fortunately, our bearings thrive in these conditions.

Similar bearings look similar

But they don’t perform the same. Want proof? We tested a wide range of standard bearings against our own and we always found the John Deere bearings had higher quality. So why needlessly risk down time? Insist on bearings from John Deere to increase performance and reliability.

Always order bearings from the source you can trust: your John Deere dealer.

Genuine John Deere bearing with 100% accurate tolerances and perfect surface

Look-alike bearing with rollers standing out of outer ring and rough surface

The benefits are many

John Deere bearings meet the highest specifications in the industry: our own. That’s why they’re suited for a lifetime of hard work and made especially for the exceptional performance levels our transmissions – and other systems – provide.

Thanks in part to the special VT 119 bearing grease and natural rubber o-rings we use, John Deere bearings keep performing long after conventional bearings have retired to the scrap bin.

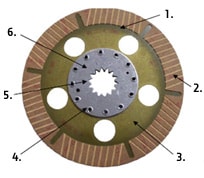

BRAKE DISCS

John Deere brake discs

- Reliable performance at all times

- Highest braking comfort without irritating noise

- Constant braking effect and good modulation

- Corrosion resistance in various environmental conditions

Design of a genuine John Deere brake disc

- JD Part Number

- Brake pad with groove pattern

- Core plate

- Riveted joint

- Teeth

- Hub

Dimensions John Deere brake disc versus non-genuine brake disc

Genuine John Deere brake discs conform to John Deere specifications, which is essential for reliable and durable performance of the complete brake system. Just small deviations in dimensions have a huge impact on the reliability of the braking effect and wear.

- Reduced wear

- Reliable braking effect and performance

- Consistent interaction of complete brake system

The core plate of the non-genuine brake disc is too thick and the friction material not thick enough. Both parameters show a relevant tolerance deviation. Furthermore, the brake disc as a whole is too thick.

- The non-genuine brake disc does not comply with John Deere specifications

- The determined tolerance deviations have a negative impact on the braking effect and the interaction of the complete brake system

- As the friction material is not thick enough, the brake disc wears out more rapidly

Friction Test John Deere brake disc versus non-genuine brake disc

The friction test simulates brake activations. The brake discs have to fulfill a minimum of 1,000 cycles.

Test criteria are:

- Wear of brake disc and brake pad

- Friction coefficient

The friction material of the non-genuine brake disc glazed after only 200 cycles.

- Indication of low-quality material

- Worsened oil-cooling effect

- Reduced thermal conductivity

- Worsened braking effect

- High wear

Durability Test John Deere brake disc versus non-genuine brake disc

In the durability test, the hub has to bear 5,000 Nm/3,688 lb.-ft. in changing directions for at least 30,000 cycles. During the test, each tooth has to bear more than 1,000 kg/2,205 lb.

The John Deere brake disc shows equal contact pattern after 30,000 cycles!

- Optimum power transmission

- High standard of workmanship

- Maximum durability

The non-genuine break disc fails after only 7,750 cycles as a result of tooth breakage.

- Loss of the complete braking system!

The non-genuine brake disc shows an unequal contact pattern at the lower and upper hub.

- Uneven power transmission

- Tooth breakage

Riveted joints

The genuine riveted joint provides high contact area for force distribution.

- Optimum force distribution and power transmission

- Highest reliability

The none-genuine riveted joint has a different shape and provides less contact area than the John Deere riveted joint!

- Worsened force distribution

- Reduced power transmission

- Less reliability

John Deere riveted joints are heat-treated and connect the hub to the core plate without backlash!

- Greater stability and durability

- Less wear

The non-genuine riveted joints are made from standard material which is not heat-treated - the result is higher wear! The connection of the hub to the core plate is not free of backlash!

- Less stability and durability for the whole brake disc

- Increased wear