Compare wheeled harvester models

| Model | Boom | Boom reach | Gross lifting torque | Cabin | Harvester head |

|---|---|---|---|---|---|

|

John Deere H7 |

8,6/10/11,7 |

217 |

Rotating and levelling, or fixed | ||

|

John Deere H9 |

8,6/10/11 |

240 |

Rotating and levelling, or fixed |

Harvester heads

John Deere harvester heads are known for their productivity, reliability and especially accuracy. The harvester heads have efficient feeding and delimbing.

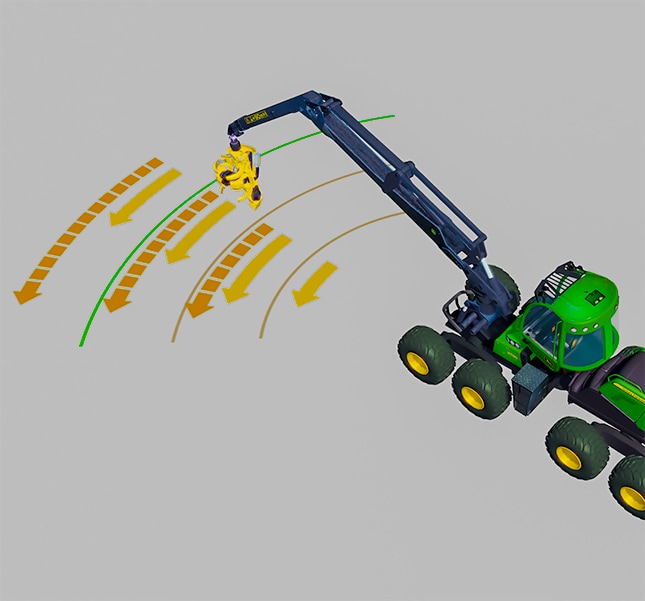

IBC 3.0 in Harvesters

Operator takes the harvester head to the desired place. Sensors recognize the location of the head and the system adjusts boom movements and extension automatically. The operation of IBC in harvesters has been adapted to harvester’s work cycle.

Leveling cabin increases work comfort

Cabin faces the work area and the automatic leveling function allows the operator to sit upright even when the machine is on uneven terrain.

Adaptive Driveline Control

Adaptive driveline control is a unique standard feature in G-Series forest machines. This control system improves the machines’ drivability and productivity.

TimberMatic Maps and TimberManager

No more guessing. TimberMatic Maps and TimberManager open a real-time view to the work site.

NOTE. Not all models and options shown are offered or available in all markets.