PowerTech M

Compliance for flexibility and cost-savings

Following a simple design, PowerTech M engines (2.4L and 4.5L) use mechanical controls for optimal performance, while maintaining the performance standards of Tier 2/Stage II engines. They feature a new mechanical injection system that generate high injection pressures and improves combustion efficiency.

PowerTech E

Emissions compliance without sacrificing performance

PowerTech E engines are equipped with an HPCR fuel injection system (4.5L and 6.8L), electronic unit pumps (2.4L and 3.0L), a two-valve cylinder head, and integrated electronic engine controls. The HPCR fuel injection system improves combustion by increasing the fuel pressure. Performance and fuel economy are comparable to Tier 2/Stage II engines. PowerTech E engines are built on platforms similar to their Tier 2/Stage II equivalents, so they are easy to integrate into the engine compartment.

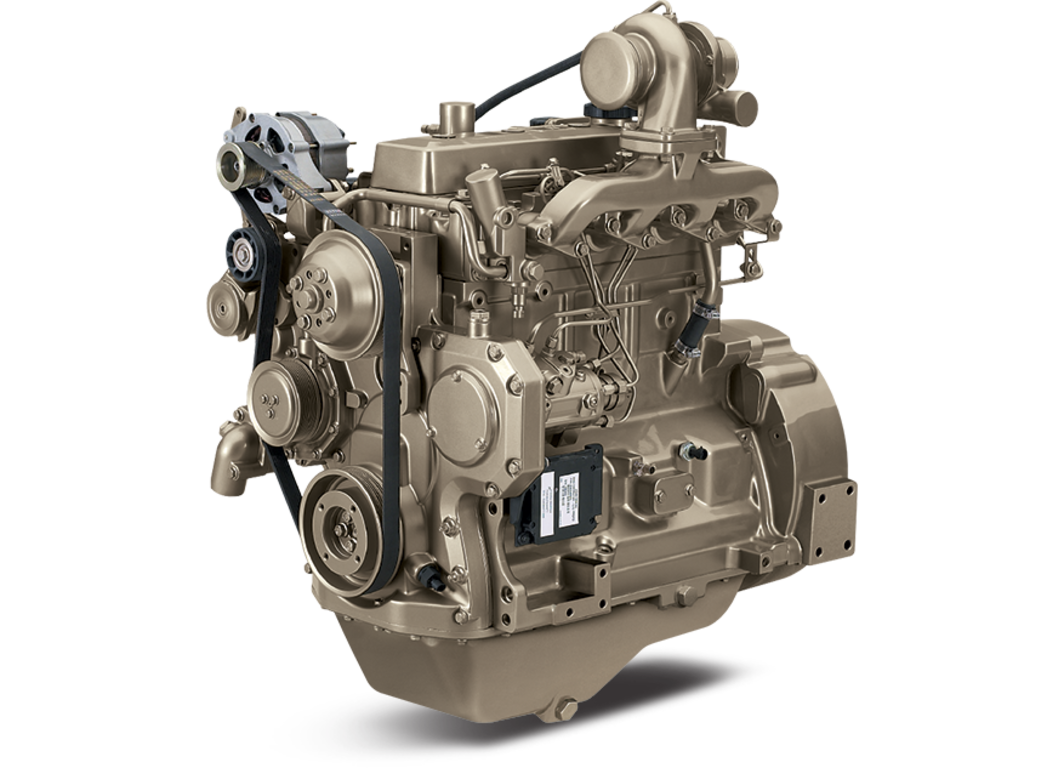

PowerTech Plus

The ultimate in emissions compliance, performance and fuel economy

PowerTech Plus, proven technology, larger displacement, better performance, and best-in-class fuel economy.

John Deere offers 4.5L, 6.8L, 9.0L, and 13.5L engines in the PowerTech Plus category, which includes cooled exhaust gas recirculation (EGR) and variable geometry turbocharger (VGT) technologies for the ultimate in Tier 3/Stage III A efficiency and performance. The higher an engine’s peak combustion temperature, the greater the amount of NOx created. Cooled EGR is an effective method of lowering peak combustion temperature. To offset the increase in particulate matter caused by the reduction of NOx, we’ve taken the following steps:

- Increased fuel injection pressure by utilizing high-pressure common rail fuel systems and electronic unit injector technology

- Improved power cylinder components, resulting in reduced oil consumption

- Adopted VGT to control transient smoke

- Improved the shape of the combustion bowl to maximize air/fuel mixing and optimize the combustion process, reducing the amount of emissions.

The PowerTech family of Tier 3/Stage III A engines meets regulations, offers you flexibility and cost-efficiency, and gives you exactly the performance you need.