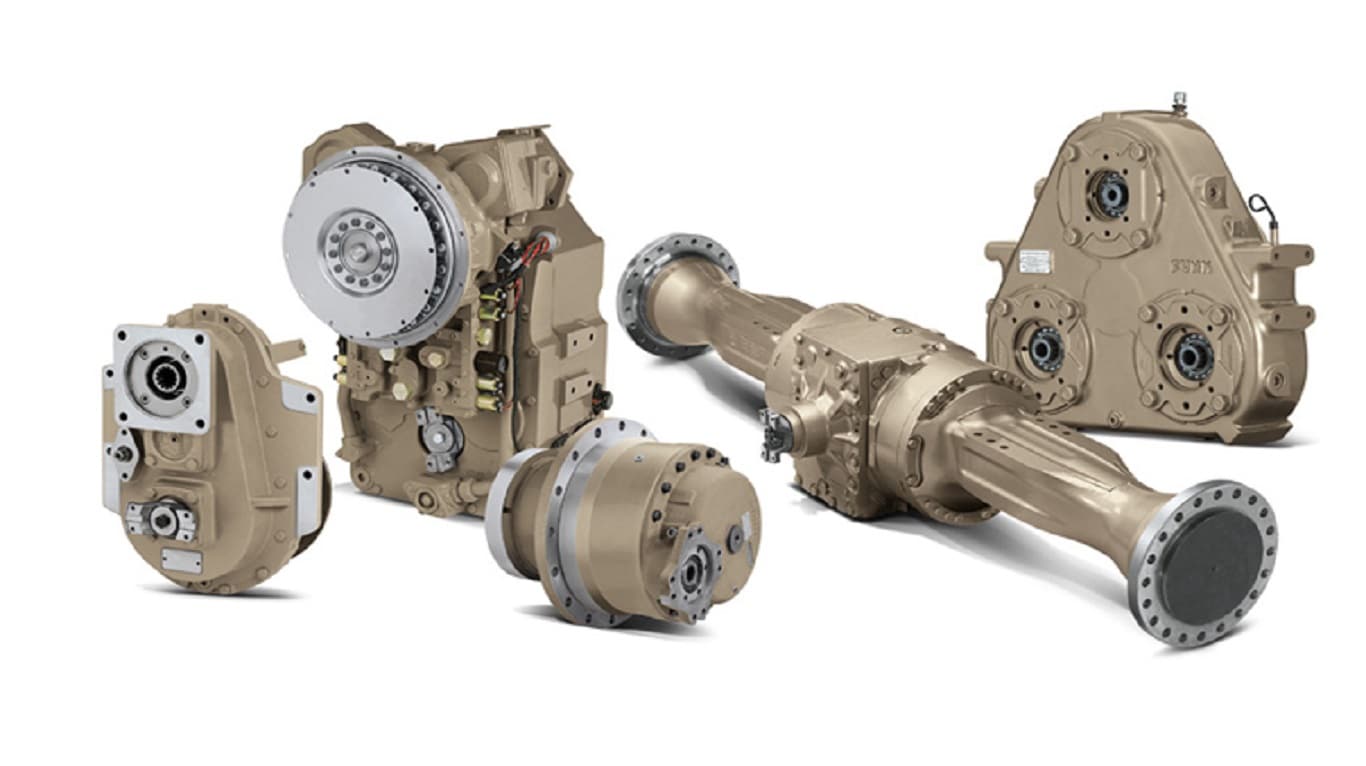

Drivetrain Components

Drivetrain Components

John Deere Coffeyville Works Inc. offers proven products with over 25 years of OEM and off-road experience. To satisfy OEM requirements, we have a strong commitment to the newest design technology, stringent testing, and expert application engineering. We also offer dedicated OEM service and long-term aftermarket support to ensure prompt response and problem solving. To see the value we can add to your equipment, take a look at our brochure or contact us directly.

POWERSHIFT TRANSMISSIONS

Reliable powershift transmissions. Your customers trust you to provide reliable, high-performance equipment with the most up-to-date components. We produce powershift transmissions that help you meet that need—and we do it with personal, attentive service, no matter what size your operation. Our powershift transmissions are available in both torque converter and direct drive options, covering applications in ag, construction, forestry, mining, aircraft ground support, railroad maintenance, and other industries.

Mounting options include engine, midship, and remote. All models in the Funk powershift transmission line feature a high degree of parts interchangeability, minimizing your parts inventory.

Our 2000 and 4000 powershift transmission series feature mechanical/electric controls, while our DF series employs an electronic control unit. The DF series can communicate with other parts of your equipment, including the engine, and includes neutral start protection, inching/clutch control, automatic or operator selective shifting, and more.

HMD TRANSMISSIONS

Funk HMD transmissions are durable and are available in two-, three-, and four-speed models.

Our HMD transmissions are equipped to operate with high-tech hydraulics, which provide the electronic controls needed for equipment such as dozing machines, motor graders, railway vehicles, sweepers, pavers, and virtually any other application where a controlled travel speed is critical.

The most popular model in our HMD lineup, the 18000 offers a generous 149 kW (200 hp) rating for powerful applications. The design includes an integral lube pump that completely lubricates input splines and bearings, increasing the life of the transmission. Two high-gear and five low-gear optional ratios produce the speeds appropriate for equipment in the forestry, construction, railroad, mining, and ag industries.

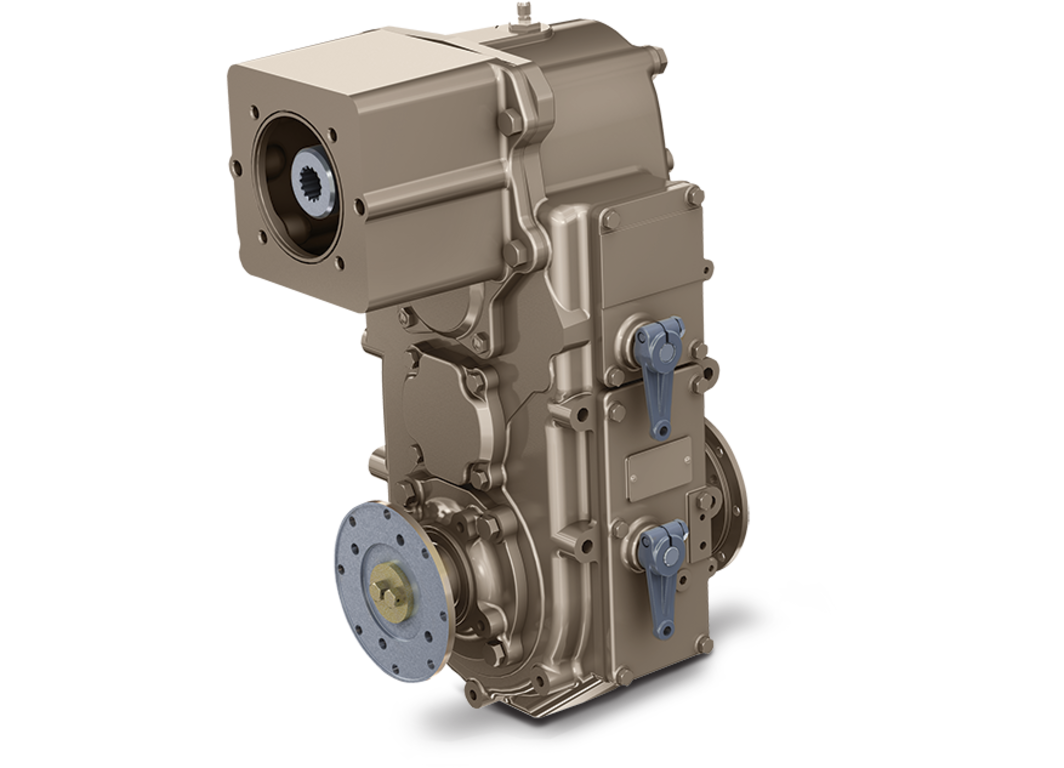

PUMP DRIVES

Some manufacturers might expect your equipment to fit their pump drives, but Funk pump drives are more flexible than that.

In fact, we take a modular approach to building our pump drives, so we can offer more than 5,000 configurations of horsepower, torque, gear ratios, hydraulic pump adapters, mounting options, and more. Built for quiet operation, our pump drives are available in five series, ranging from 135-950 kW (101-708 hp) and are equipped to operate from an independent mount or direct-engine mount, or as a clutch-driven unit.

The many advantages of modular design.

The combination of the latest technology and modular manufacturing techniques enables us to offer our pump drives at very competitive prices, and our wide selection means you never have to pay for a pump that’s larger than you need.

PLANETARY DRIVES

Seven models. Three types.

Whether you need reducer drives, swing drives, or track drives, you can count on Funk planetary drives to deliver durability, performance, and superior engineering. Our drive designs include various ratios of input gear reduction sets, along with single and multiple combinations of center section planetary gears that drive power through output arrangements to accommodate your reducer, swing, and track drive applications.

Planetary Gear Reductions

Some typical applications of Funk planetary drives include conveyers, cranes, crawlers, excavators, road rollers, track vehicles, winches, and many others in the agriculture, construction, industrial, marine, mining, and petroleum industries.

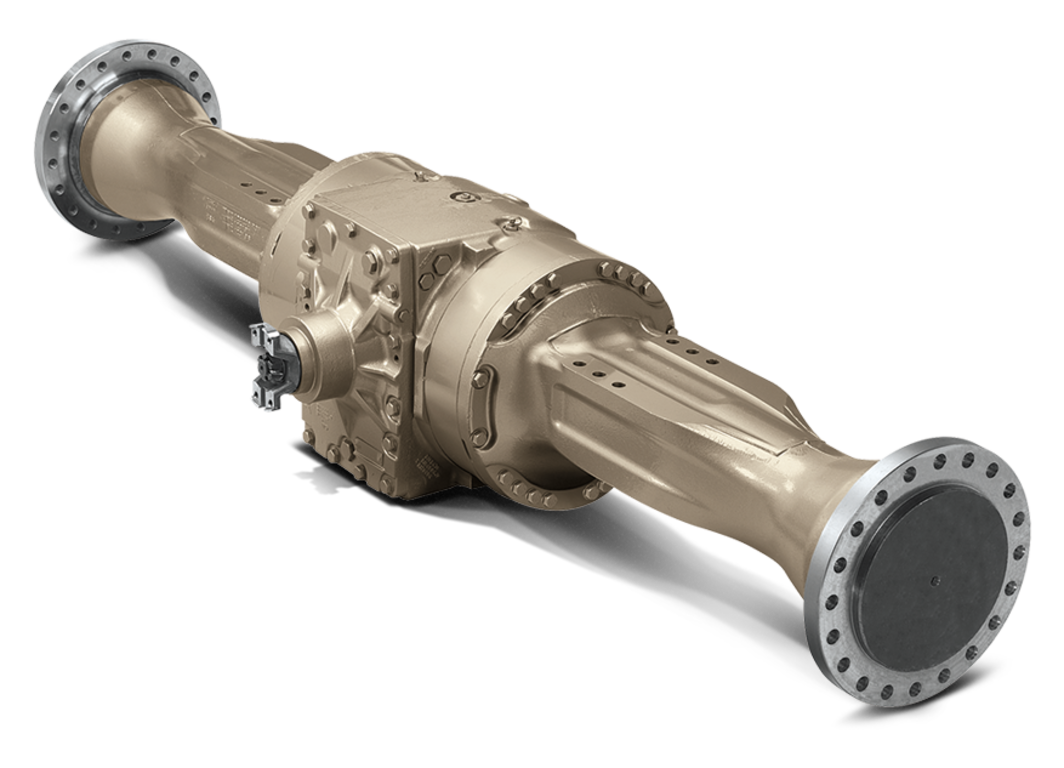

AXLES

And the inboard planetary axles from Funk are as tough as they come.

Our TEAMMATE™ II family of axles has proven itself over and over—and under the most stringent conditions. Their strength and durability have made them a fixture in the forestry, ag, oil field, mining, and construction industries, as well as in a number of speciality applications.

Our high-torque, low-speed axles are designed using a building-block concept that enables us to offer thousands of configurations and, essentially, to custom-build an axle to fit your torque and load requirements precisely.

All Funk axles are non-steerable, and are built strong to contribute to the rigidity of your equipment’s frame. And because they offer wide bearing spacing, they give you additional track width flexibility.

For low ground pressure applications, ask for SWEDA.

SWEDA is our Super Wide Extreme Duty Axle, and it’s ideal in situations where your vehicles must leave only a minimal footprint without sacrificing rugged performance. Dual and wide tires can help in such situations, but they create additional demands on the axle—and that’s where SWEDA comes in. For skidders, oil exploration, and other demanding applications, make sure you ask for SWEDA.