W2 400

With W2 400 combine you can harvest a variety of crops such as corn, soybeans, wheat, barley etc. in toughest field conditions. It come with a range of features that will boost your daily productivity while keeping the loss at minimum levels. The combine is powered by a reliable and fuel efficient engine from John Deere that generates sufficient power to run all combine functions.

We paid special attention to operator’s comfort in the cab, and now you can comfortably run the entire shift with minimum fatigue. Our new design has made the combine more maintenance friendly and with routine checks, the combine can run smoothly throughout the harvesting season.

Combine Systems

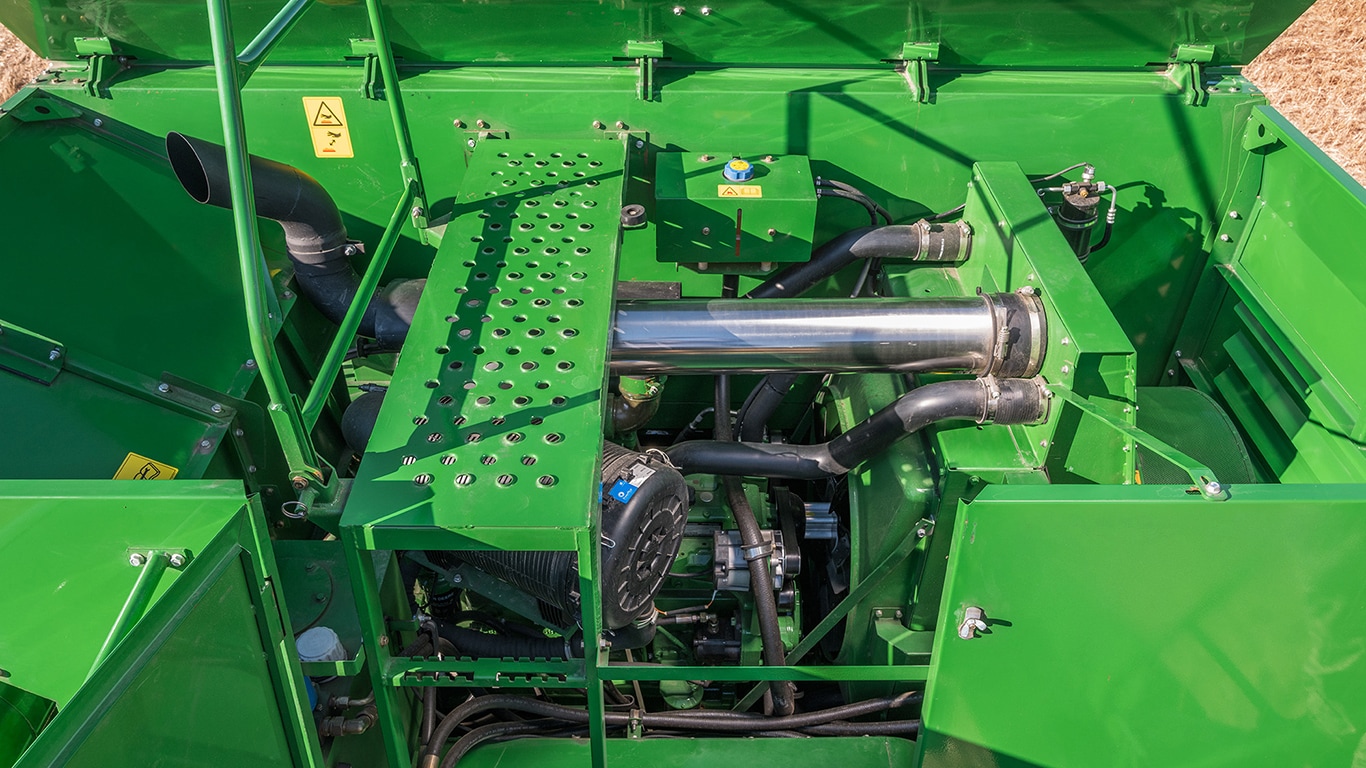

Powered By Strong And Reliable Engine

W2 400 combine is powered by 6.8L John Deere PowerTech E engine. This engine delivers sufficient power to harvest in varying field conditions while offering best in class fuel economy. A high pressure common rail fuel injection system manages fuel injection cycles and positively contributes to the fuel economy while fixed geometry turbocharge provides excellent engine performance across the entire torque curve allowing the combine to harvest confidently in the toughest field conditions.

Comfortable Working Environment

Large and spacious cab offers operators maximum comfort during long harvesting hours. The operators have good visibility of the surroundings from the cab, all controls are easily accessible from the operator’s seat. Corner post display, displays vital machine and harvesting parameters in real time allowing operators to quickly react to the changing conditions for optimal performance. The combine is equipped with air conditioner and heater to provide operators with maximum comfort.

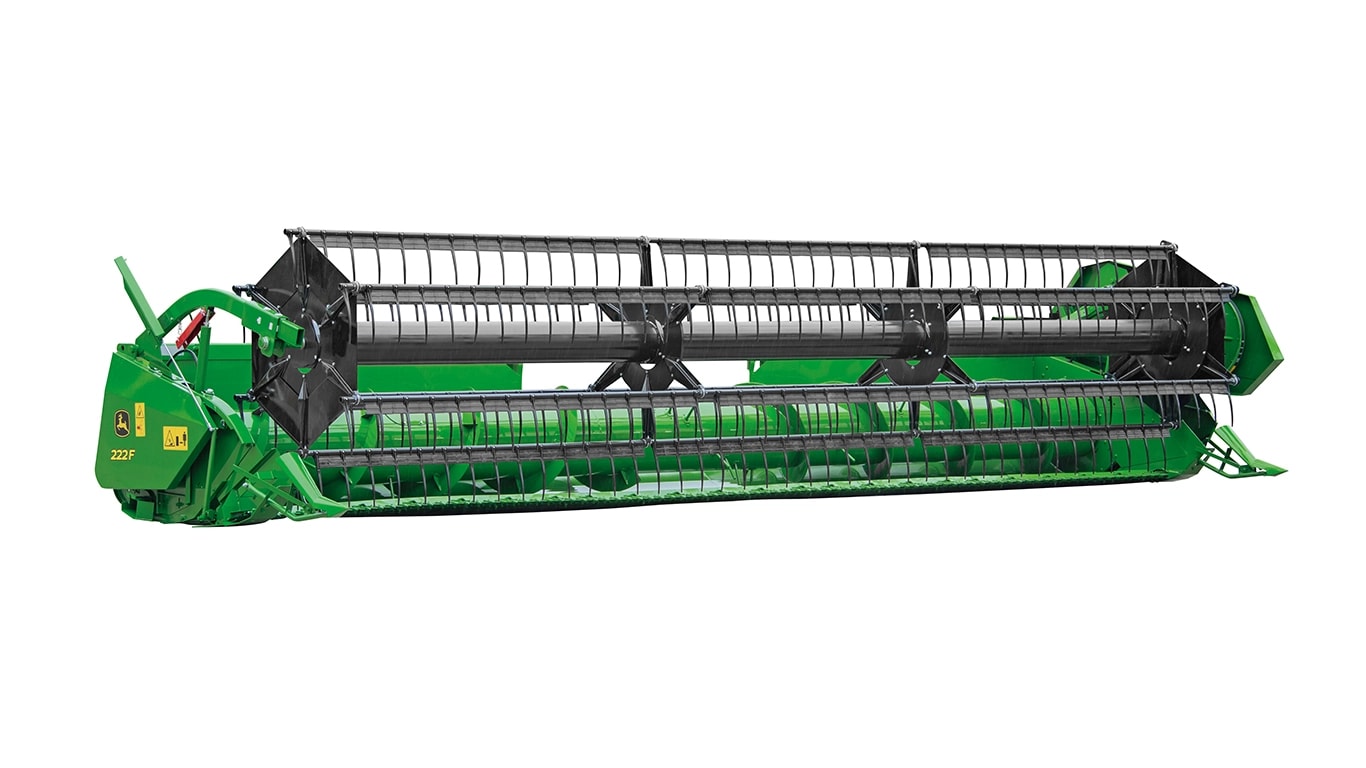

Variety Of Header Choices

W2 400 can be equipped with flexible or rigid headers. Rigid header is built for extra wear resistance and delivers uninterrupted crop flow into the combine, even in tough and wet conditions whereas flexible header is a great choice for harvesting low hanging soybeans pods. The operators can also lock the cutterbar and harvest other small grains. Both rigid and flexible headers come in three different sizes, 4.6m, 5.3m and 6.5m. Additionally, belt pickup is also offered to gather windrowed grains.

Smooth and even feeding

1300 mm wide feederhouse ensure smooth and even feeding in different crop conditions. The floating drum on the feederhouse provides large areas of clearance for uninterrupted high volume crop flow. The closed front drum design ensures less wrapping and higher protection against stones and other foreign objects. Stone trap protects the threshing system by effectively catching stones and is easily accessible for cleaning.

With Feederhouse Reverse feature, offered in base on all W2 400 combine, the operators can easily resolve any plugging issues from the cab thereby minimizing downtime.

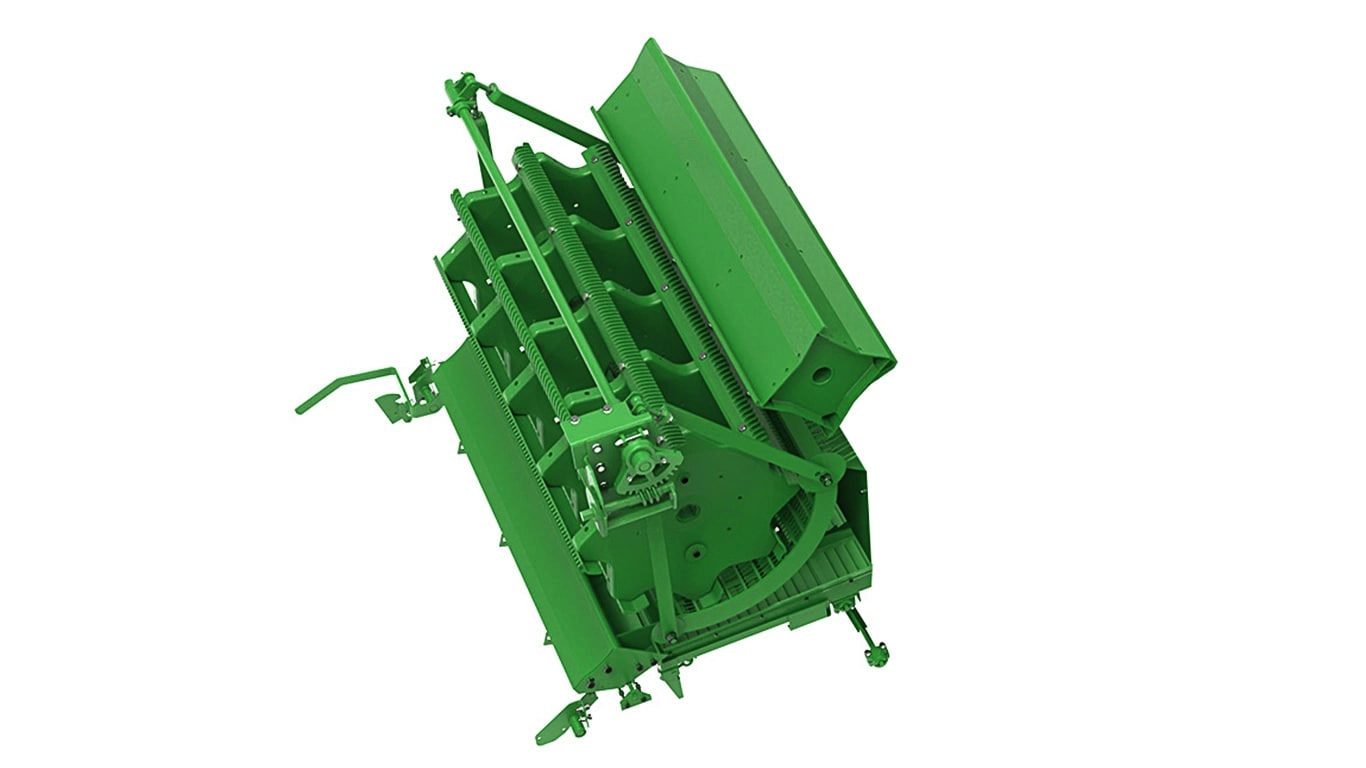

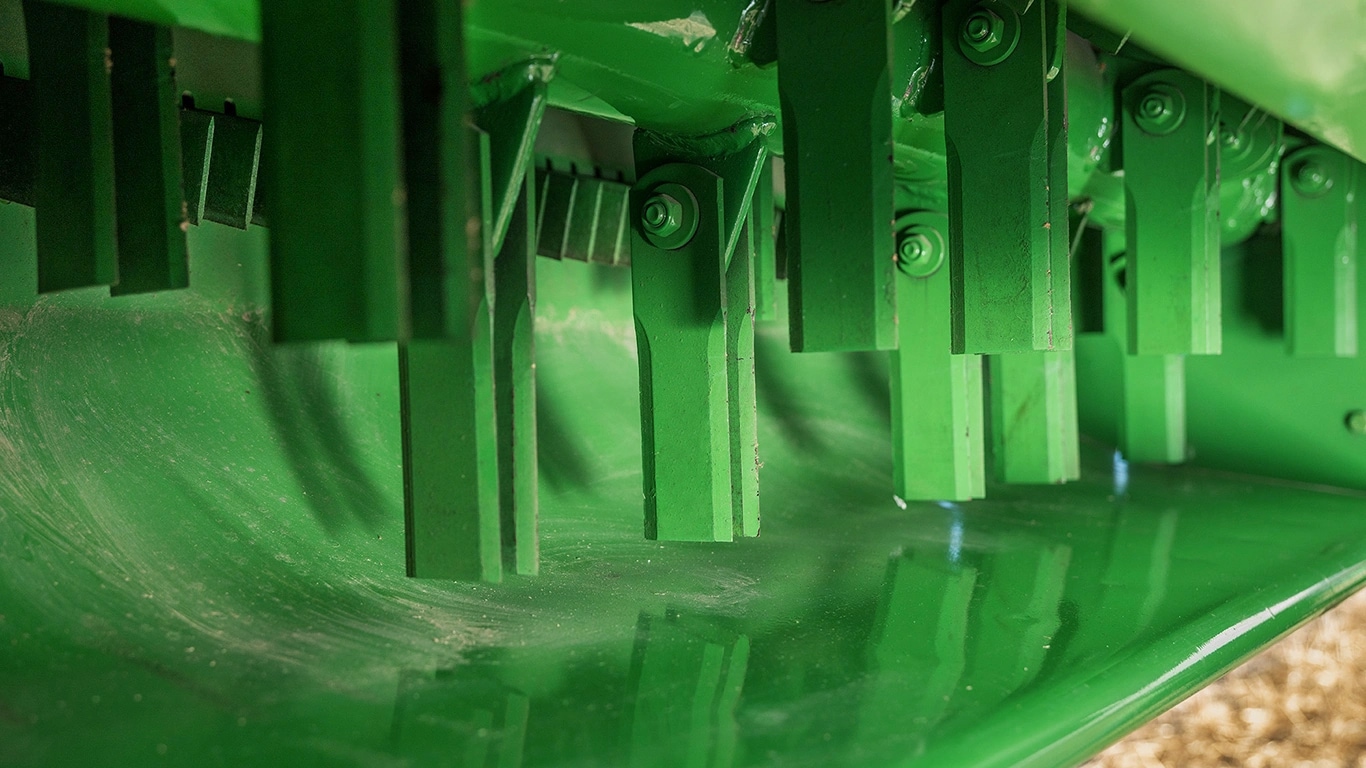

Threshing

Large threshing cylinder with 8 rasp bars provide excellent threshing quality in different crops and conditions. 111° concave wrap angle provides a large threshing area to maximize threshing performance. Depending upon crops being harvested, the operators can either select small wire concave recommended for harvesting small grains or large wire concave recommended for harvesting crops like corn. There is a separate rice package available for rice growers.

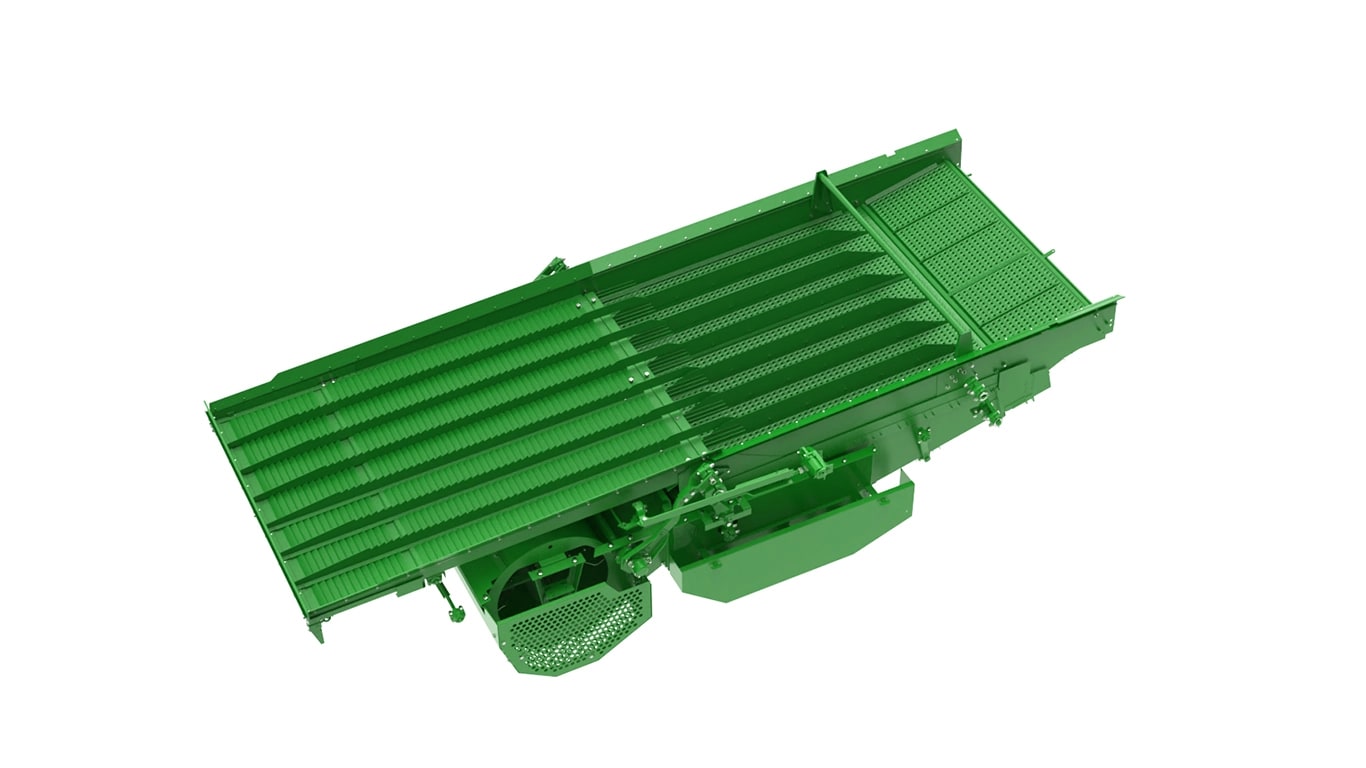

Separation

The W2 400 combine has five straw walkers that are designed to handle all crops. The five straw walkers shake the straw mat and remove any loose grains as the straw mat moves towards the rear of the combine. Optionally, fishback straw walker and power separator are also offered to further enhance the separation quality, especially recommended for fields with high yields. The combine is also equipped blockage detection system which triggers an alarm and stops the threshing cylinder upon blockage detection in the walker

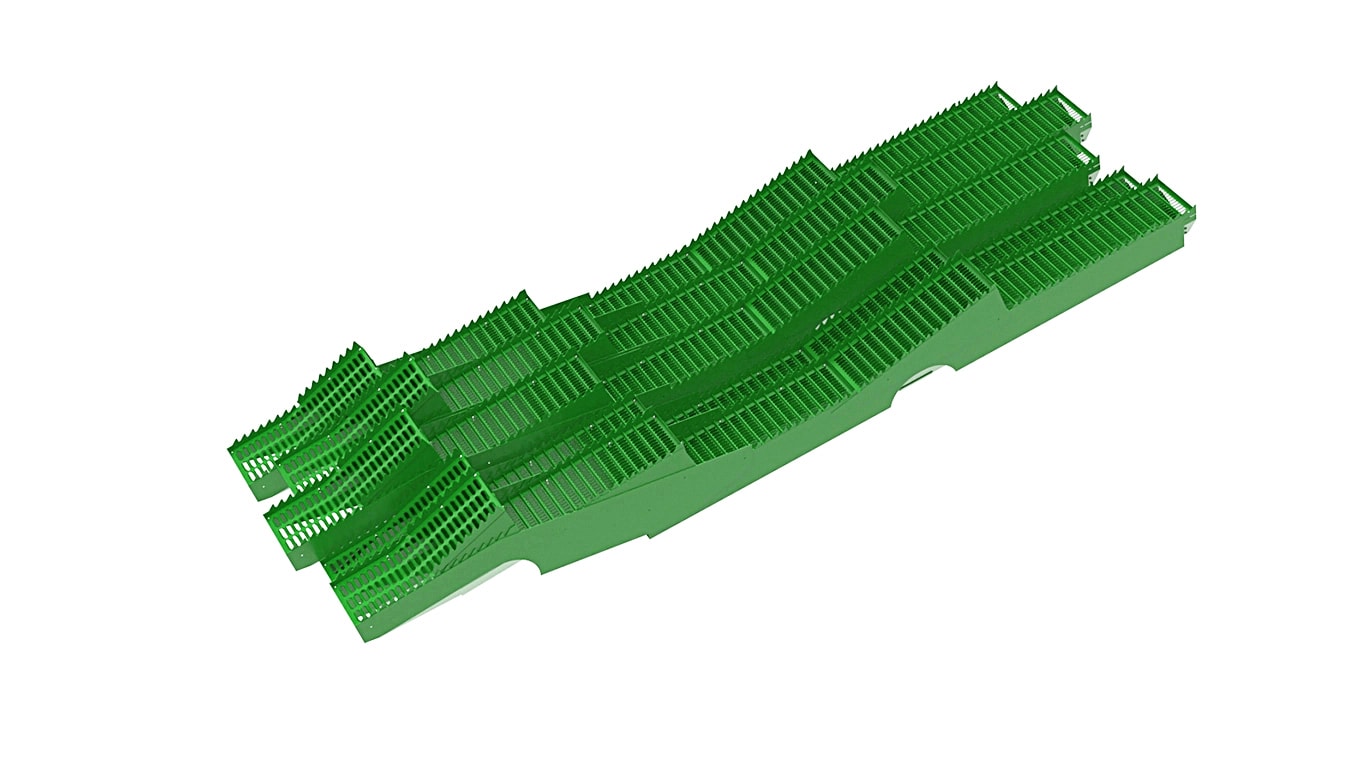

Cleaning

The large cleaning area of 4.3 m2 allows the W2 400 combine to harvest faster and in fields with high yields with minimum losses. Operators can adjust the cleaning shoe fan speed from the cab, on the go as per the changing field conditions. The cleaning fan housing with adjustable wind board provides even air stream distribution to the full width of the cleaning shoe.

Harvest More Hectares Per Day

The large grain tank with 6000L capacity allows the operators to harvest more hectares per day without the need to frequently stop and unload the grains. The grain tank level sensors mounted inside the tank, monitors the current tank level and alerts the operator and the grain cart driver when the tank reaches full capacity. There is also a small window inside the cab from which the operators can monitor the grain tank level as it fills. With high capacity unloading auger, the operators can quickly unload the grain tank and continue harvest.

Residue Management

The W2 400 combine has four rows of 52 knives and 49 counter knives with a choice of high speed at 3100 rpm and optional low speed at 1800 rpm. This provides better chopping quality and more versatility while harvesting different crops.

Chop To Drop Feature

The operators can easily adjust the deflectors position using a single lever and guide the straw either to the chopper or down to the ground for bailing.

Straw residue deflector with manually adjustable fins evenly distribute the residue in the field up to 6.7 m. The deflector can be folded during transportation and storage after the season.

Excellent Visibility During Night

Six roof mounted halogen lights provide operators good visibility during night operations. Additionally, the combine is equipped with a light inside the grain tank that allows the operators to see clearly as the grain tank fills during night. There is a dedicated side light near the unloading auger that lights the entire unloading area during unloading at night. Two lights on the rear of the machine ensures good view of the residue management system and also ensures safe reverse.

Simple And Easy Access

Operators and technicians can easily access the engine compartment and other combine sections such as fuel tank, grain tank, air filters etc. and perform regular maintenance or repair work. regular maintenance keep the combine in good condition and the combine runs smoothly throughout the harvesting season.

Get the full story

Want to learn more ? Click on the link below to download the product brochure

Specifications

| ENGINE | |

|---|---|

|

ENGINE TYPE |

John Deere PowerTech E 6-cylinder engine |

|

EMISSION LEVEL |

Tier 3/Stage IIIA |

|

RATED SPEED |

2400 rpm |

|

RATED POWER |

199 hp |

|

POWER BOOST |

10 hp |

|

FUEL CAPACITY |

400 L |

| FEEDING | |

|---|---|

|

DRIVE TYPE |

Fixed |

|

STONE TRAP |

Standard |

|

REVERSER |

8 hp |

| THRESHING & SEPARATION | |

|---|---|

|

CHANNEL WIDTH |

1300 mm |

|

THRESHING CYLINDER |

610 mm |

|

THRESHING CYLINDER |

Single-speed cylinder drive: 495 to 1140 rpm |

|

CONCAVE AREA |

0.77 m2 |

|

BEATER FINGER RAKE AREA |

0.35 m2 |

|

TOTAL ACTIVE |

1.02 m2 |

|

NUMBER OF WALKERS |

Five |

|

WALKER AREA |

4.75 m2 |

|

WALKER AID |

Power Separator (Optional) |

| CLEANING SYSTEM | |

|---|---|

|

CHAFFER |

2.42 m2 |

|

SIEVE |

1.87 m2 |

|

TOTAL CLEANING AREA |

4.3 m2 |

|

CLEANING FAN SPEED |

440 to 1200 rpm |

| GRAIN HANDLING | |

|---|---|

|

GRAIN TANK SIZE |

6,000 L |

|

UNLOADING RATE |

75 L/s |

|

UNLOADING AUGER |

110º |

|

UNLOADING AUGER LENGTH |

4.1 m |

|

TRANSMISSION |

Manual four-speed transmission |

|

MAXIMUM SPEED |

24 km/h |