Efficient cleaning system delivers cleanest cane ever

Elevator and cleaning system

High-capacity elevator

Primary extractor

The CH570's reliable cleaning system yields the cleanest cane in the industry. Cleaner cane, less billet loss, and less downtime will bring more profit.

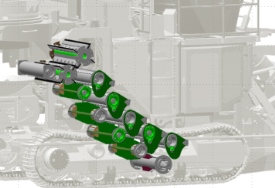

Primary extractor

The largest primary extractor in the industry

Wider blades and conical hub

The CH570 boasts the largest primary extractor fan in the industry — using four blades that measure a staggering 152 cm (5 ft) in diameter. This fan cleans at lower speeds, reducing horsepower consumption and cane losses.

The fan speed can be adjusted effortlessly from the cab to adapt to the different cane conditions by simply varying the pump displacement. The fan is driven by a robust and efficient hydrostatic system with piston pump and motor.

The fan is mounted directly to the motor shaft, which means no bearings, no blade balancing, less vibration, and fewer components. The motor drive support system features four rubber-mounted legs to improve fan stability and reduce vibrations. The primary extractor fan's motor is internally mounted and does not need to be removed for transport.

The conical hub cover reduces air voids and recirculation while the wide-design blade produces more airflow at lower rpm. The hard-surfaced blades combined with operating at much lower speed results in significantly longer blade life.

Smart power primary extractor setting

The smart power primary extractor feature is available to automatically reduce the extractor fan speed to a preset minimum when the elevator is turned off.

Elevator

Robust structural tube frame elevator with perforated floor

Heavy-duty swing table

The CH570 features a high-capacity structural tube-frame elevator for extended durability. The elevator's perforated floor allows additional dirt to fall through after primary extraction. The top and bottom idler sprockets reduce wear and prolong the elevator's chain life.

The tall sidewalls and 18-cm (7-in.) reversible slats will handle the heaviest cane, keeping billets from toppling over and falling back down the elevator. All of this sits on the CH570's heavy-duty swing table, designed to withstand the heaviest loads and toughest field conditions. The swing table also features an exclusive slew wiper to keep the area clean.

The elevator hoses are routed inside the solid frame, promoting longer life by improving protection and minimizing exposure. Bolt-on elevator extensions are also available to provide additional reach for wider row spacing. The extensions are 30.5 cm (12 in.) for wheel or track units; and 61 cm or 86 cm (24 in. or 34 in.) for track units only. The 61-cm (24-in.) extension can be ordered for a wheel harvesters but it requires the less secondary extractor option.

On the CH570, the elevator controls were moved from the floor pedals to the multifunction control lever for ease of operation. The control switches feature a double-detent system so that the elevator swings approximate 90 degrees without having to hold the switch depressed continuously. The above will help the operator to concentrate on other functions when turning around on the headland while the elevator is rotating.

More features

Grease cylinder chain tensioning

Nitrogen accumulator The CH570's elevator also has a grease cylinder for easy elevator chain tension adjustment and a nitrogen accumulator to minimize shock loads.

Secondary extractor

Secondary extractor and bin flap

Optional without secondary extractor

The secondary extractor provides even more cleaning prior to loading. Its unique design allows trash to be blown away from the wagons more efficiently. The hood rotates a full 360 degrees, so it can be set at any angle.

The hydraulically adjustable bin flap directs billets into the wagon. The ideal fan speed allows the best cleaning with low horsepower consumption. For growers who burn cane, a less-secondary-extractor option is available.